A Small Mystery Solved at the Panghyon Aircraft Factory

Key Findings

- The helicopter rotor blade test rig at the southern end of North Korea’s Panghyon Aircraft Factory is a critical component in maintaining the Korean People’s Air and Air Defense Force (KPAF) helicopter force.

- The current helicopter rotor blade is the not the factory’s first – there have been at least three such test rigs at Panghyon dating as far back as 1983.

- The somewhat cyclical appearance suggests periodic force-wide maintenance, repair, overhaul (MRO), and upgrade programs.

In late 2019, a small object located at the southern end of North Korea’s Panghyon Aircraft Factory, internally known as the 6 January Factory, was reported in some North Korea focused social media.1 While there was some speculation as to what it was (e.g., a new ballistic missile launcher, rocket engine test stand, VHF radar, etc.) no firm judgement was reached in these discussions and the subject quickly faded from interest.2 The simple answer is that the unidentified object, which remains today, is a helicopter rotor blade test rig. Depending upon the nation, size, time period, and capabilities, these test rigs are sometimes identified by various names such as helicopter rotor test cages, rotor blade test systems, dynamic test rigs, and rotor blade whirl towers, among others.

These test rigs are used to support helicopter main rotor hub system development and testing, rotor blade development, dynamic blade balancing (after manufacture, repair, overhaul, or upgrades, etc.), and performance analysis. Depending upon requirements, they can be simple or complex systems and small or large.

The current helicopter rotor blade test rig is not the factory’s first. In fact, there have been three, potentially four, such test rigs at the Panghyon Aircraft Factory dating as far back as 1983. To more completely understand the development of a helicopter rotor blade test capability at the Panghyon Aircraft Factory, Beyond Parallel studied a large collection of declassified and open source reports, reviewed interview data, and analyzed ten declassified satellite images acquired from 1974 through 1984, as well as 39 high-resolution pan-sharpened multispectral and panchromatic commercial satellite images acquired from 2002 through 2022.

The helicopter rotor blade test rigs at the Panghyon Aircraft Factory have been critical components in maintaining the Korean People’s Air and Air Defense Force’s (KPAF) helicopter force. The rigs’ somewhat cyclical appearance suggests periodic force-wide maintenance, repair, overhaul (MRO), and upgrade programs. Although helicopter rotor blades have been at times manufactured elsewhere (e.g., the Pukchung Machine Complex/8 August Factory) and other facilities have occasionally undertaken helicopter depot-level maintenance, no additional rotor blade test rigs have been identified in readily available satellite imagery to date.

Panghyon Aircraft Factory

The Panghyon Aircraft Factory (39.876828, 125.258178) is located in the northwest corner of North Korea in Kusong-gun, Pyongan-bukdo (Kusong county, North Pyongan Province). Since its establishment, the factory has remained North Korea’s primary aircraft, helicopter, and unmanned aerial vehicle (UAV) manufacturing, assembly, depot-level maintenance, repair, and overhaul facility. It is supported by a nationwide network of factories and institutes that supplies it with equipment, parts, technology, and skilled researchers, technicians and workers. The factory’s importance to the Kim regime was evident when, in 2018, the Panghyon Airbase and its maintenance facilities known as the 4 April Factory were administratively incorporated into the capital city of Pyongyang-jikhalsi. This was apparently undertaken to provide the factory’s personnel with all the elevated privileges and rights of being Pyongyang residents rather than of a small town in North Pyongan Province.3

The stimulus for the construction of the Panghyon Aircraft Factory and much of North Korea’s heavy weapons programs dates to December 1962 when Kim Il-sung presented a new national military policy known as the “Four Military Lines.” The policy called for “…the arming of the whole people, the fortification of the entire country, the training of all soldiers as a cadre force, and the modernization of arms.”4 Subsequently, during a youth rally on April 13, 1968, Kim stated that “Now we can produce as much various military supplies as we need for our national defense by ourselves.” Six months later, he reiterated these thoughts at the Kimchaek Engineering College, stating that, “It is time for us to produce helicopters, other warplanes and modern weapons, including rockets….”5

In the wake of these policy decisions, the Korean People’s Air and Air Defense Force (KPAF) began acquiring Chinese Mi-4/Z-5 HOUND helicopters in 1974, Polish Mi-2 HOPLITE helicopters beginning in 1977, and illegally acquiring US Hughes MD-500 Defender helicopters beginning in 1983. By mid-1985, the KPAF deployed a sizable helicopter force consisting of 104 Mi-2, 53 Mi-4/Z-5, 13 Mi-8 HIP, and 87 MD-500 (20 Model 500Ds, 66 Model 500Es, and 1 Model 300C).6

To support the ambitious simultaneous goals of producing “…helicopters, other warplanes…” and rapidly expanding the helicopter force, construction of an aircraft factory at Panghyon began in 1973. The construction stopped shortly after it began for unknown reasons but had resumed by 1981, proceeded rapidly, and was completed sometime during the mid-1980s. Even before its completion, the factory was involved in various small-scale aircraft and helicopter assembly, maintenance, and repair activities.7 Since the late-1980s, it has been involved in all aspects (to varying degrees and levels of success) of the assembly, manufacture, testing, maintenance, repair, and overhaul of KPAF and Air Koryo (the national air carrier) aircraft, helicopters, unmanned aerial vehicles (UAVs), engines, and components.8

Rotor Blade Test Rig

During the late 1970s and early 1980s, the development of a helicopter assembly and MRO capability was undertaken at the Panghyon Aircraft Factory, which was then under construction. This development was to undertaken to allow for the expansion of the helicopter force and support the subsequent production of the Hyoksin-2 (a variant of the Mi-2).9 A key component of this helicopter MRO capability was the construction of a helicopter rotor blade test rig between March and June 1983 at the southern tip of the facility near the helicopter operations building and the recently completed final assembly/checkout building.10 The test rig consisted of a circular hardstand within a semicircular earthen revetment with the test rig in the center. In late 1983, a second probable rotor blade test rig was reported to be in the early stages of construction.11 However, this report appears to be inaccurate as subsequent reports make no mention of it.12 Regrettably, available high-resolution declassified KH-9 satellite imagery of the Panghyon Aircraft Factory from 1983 and 1984—the latest years such imagery is presently available for—provides only a limited view of what is believed to be the rotor blade test rig.

Readily available satellite imagery from the mid-1980s through the late 1990s is generally limited to the Landsat and SPOT systems. This imagery is of insufficient resolution to provide any significant information on the presence or operation of such a small object as any rotor blade test rig at Panghyon. Regardless, it is probable that the first test rig operated into at least the late-1980s.13

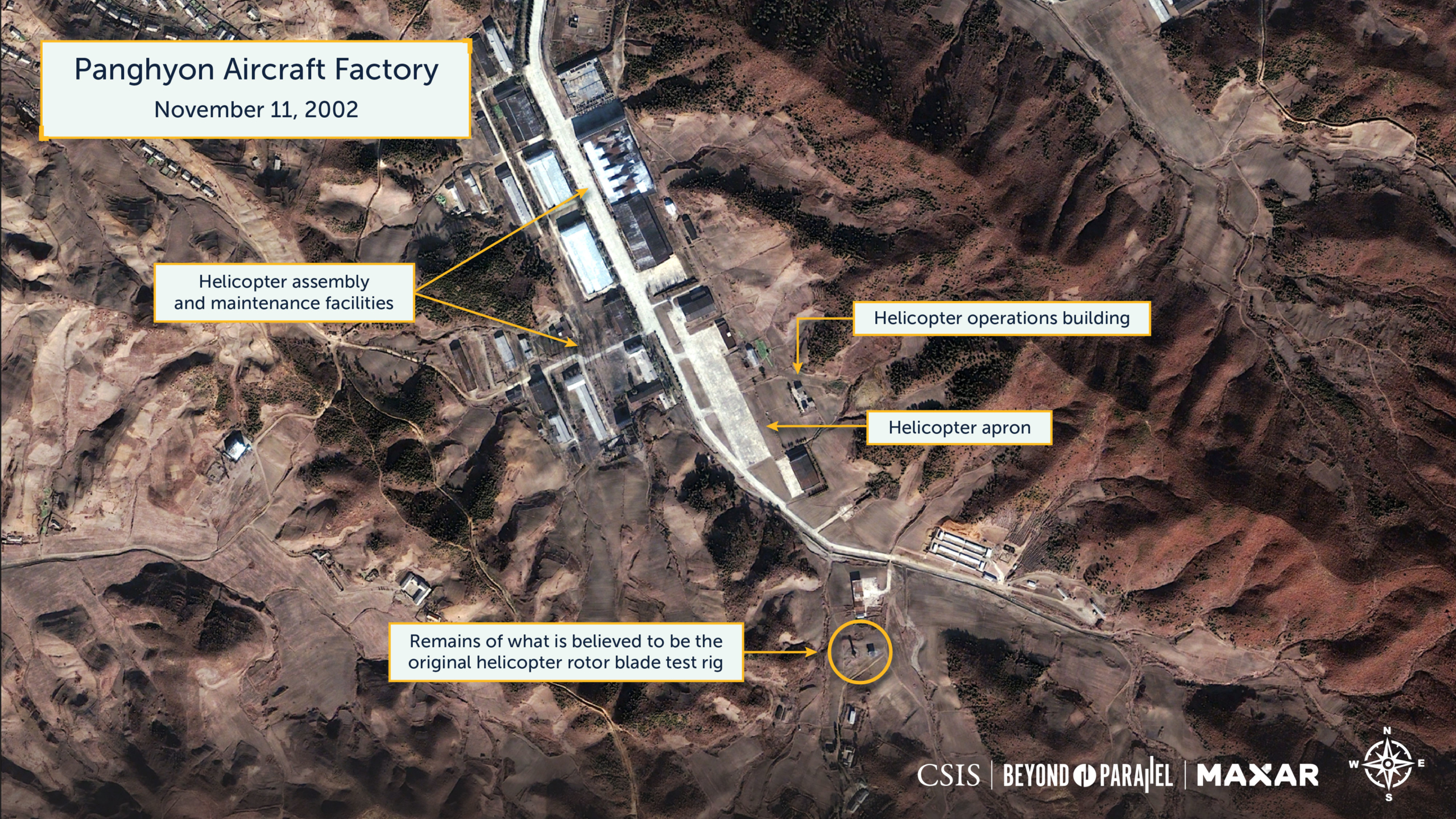

High-resolution (less than 1-meter ground sample distance) commercial satellite imagery became available in late 1999, and the first readily available cloud-free public satellite image of the Panghyon Aircraft Factory was collected on November 9, 2002. This image shows the original rotor blade test rig in the process of being razed, with its circular revetment having been partially removed and only the tower remaining. Adjacent to the test rig are a probable control building and a nearby support building. The size and shape of the test rig are somewhat similar to other such facilities seen elsewhere in the world during the period. Satellite imagery taken a year later, on November 23, 2003, shows that the original test rig had been completely razed.

Then, an image collected on March 7, 2008, showed what would subsequently be identified as the first indications of the construction of a new rotor blade test rig. This time, however, it was being constructed on the southeast side of the factory’s former helicopter apron approximately 360-meters to the north northwest of the original test rig’s location.

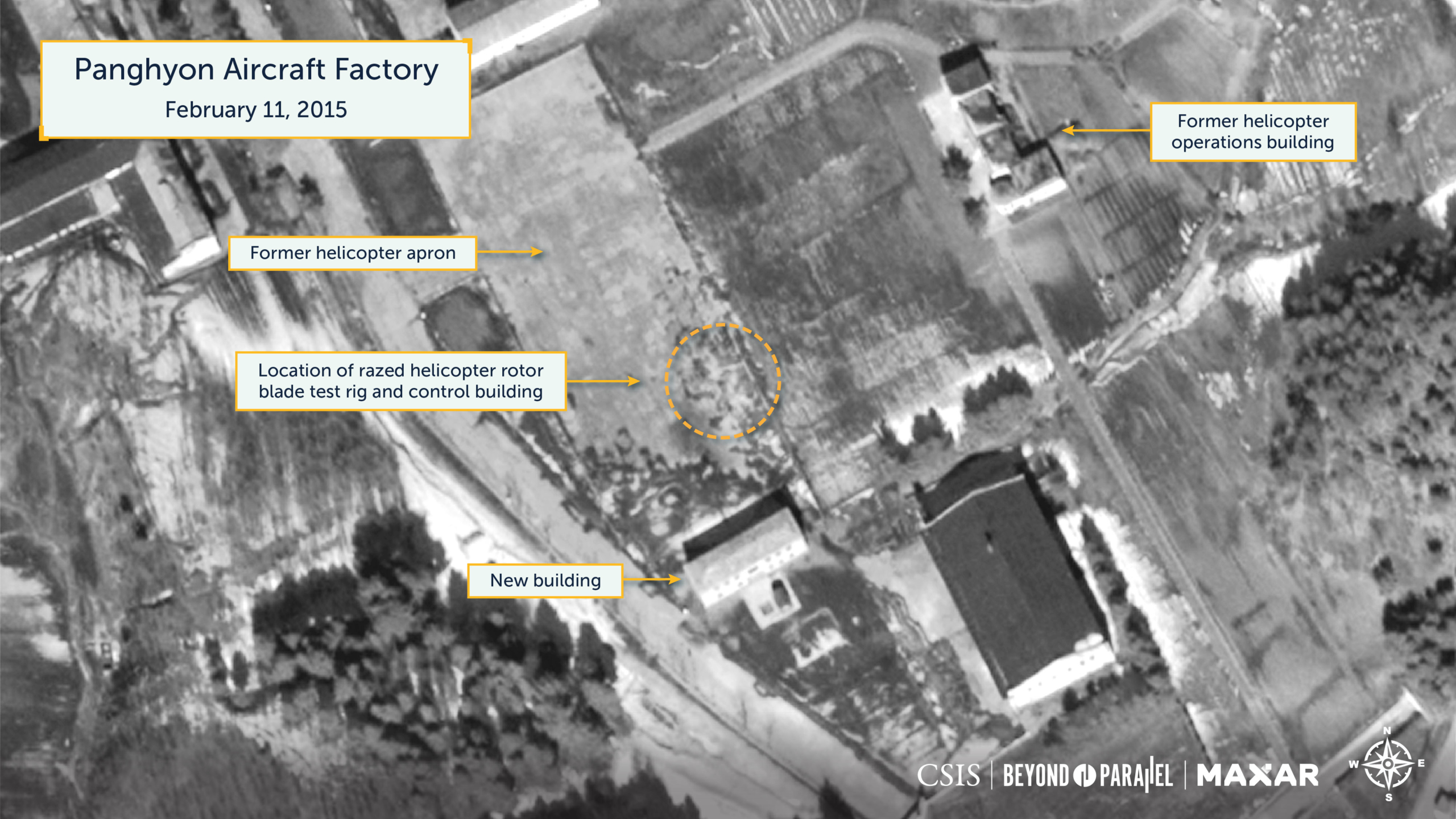

Construction of this new test rig was completed by August 31, 2009, and consisted of a small, caged, rotor blade test rig with an adjacent control building. Satellite imagery shows that this test rig remained through June 13, 2014. Sometime between that date and the first two weeks of February 2015 it was razed. Around the same time, a new two-story building, approximately 30-meter-by-10-meter, was erected along the south side of the apron, although it does not appear to have had any relationship to the test rig.

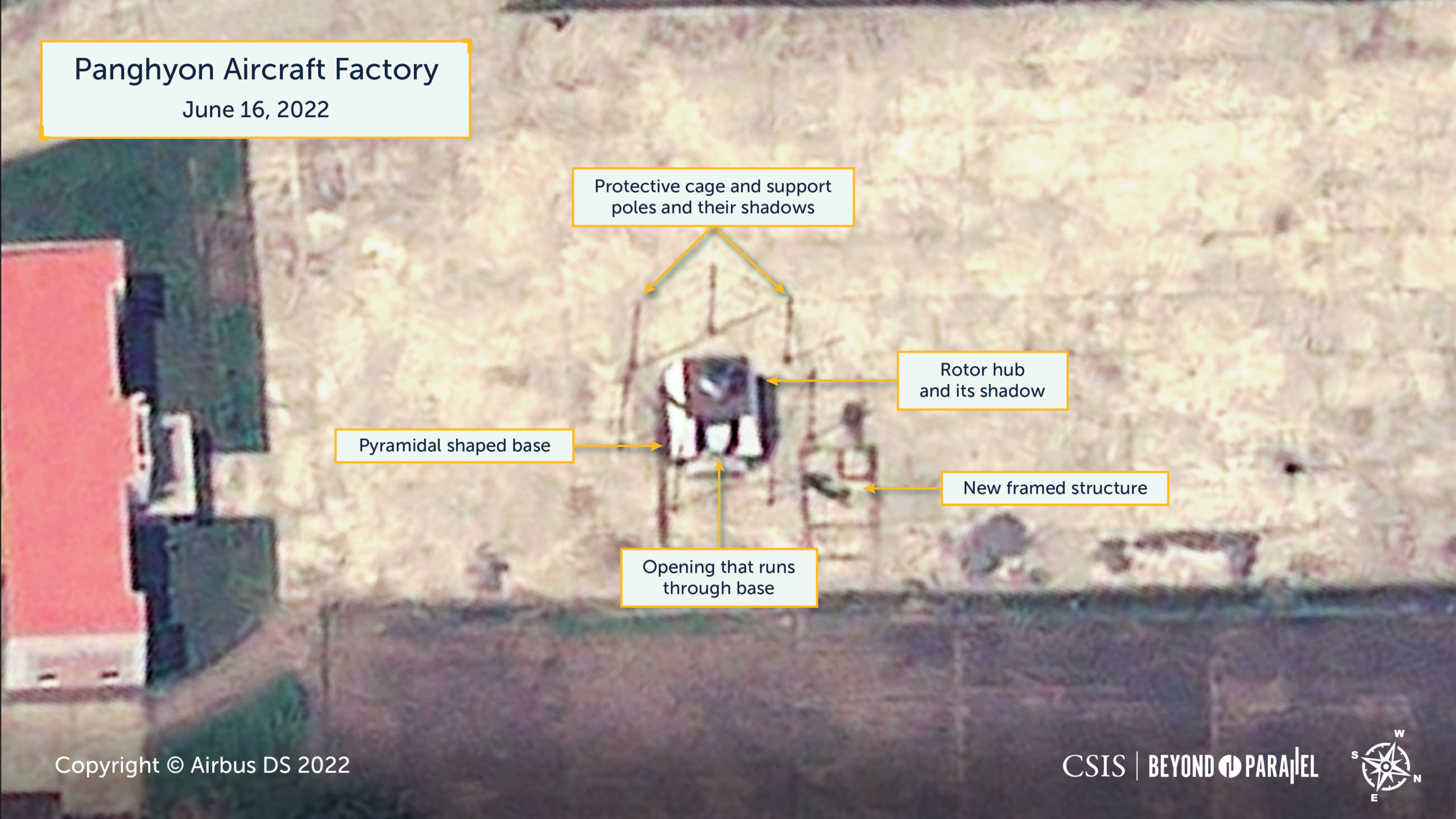

About four years later, a satellite image acquired on January 31, 2019, showed excavation work on a foundation of a new rotor blade test rig. However, this time, the rig was placed in the south center of the apron. Additional construction activity is noted on the former helicopter apron and adjacent to the former operations building. By May 23, 2019, construction of the new rotor blade test rig was complete.14

Shortly afterwards, the building on the south side of the apron was razed and replaced with a larger, approximately 35-meter-by-11-meter building with an attached 45-meter-by-17-meter arched roof workshop-type structure. Given the timing of its construction, location, and layout, it is likely to support the operations of the new rotor blade test rig.

Sometime during early 2022, a small low framed structure was built adjacent to the test rig. While its exact purpose is unknown, it has been suggested that it is a rack upon which to position rotor blades pre- and post-test.15

As seen in an image acquired on November 30, 2022, the helicopter rotor blade test rig and associated building are still present. Except for the small low framed structure adjacent to the test rig and minor excavation/construction activity on the northeast corner of the apron, nothing of significance has changed since late 2019.

Panghyon Helicopter Rotor Blade Test Rig

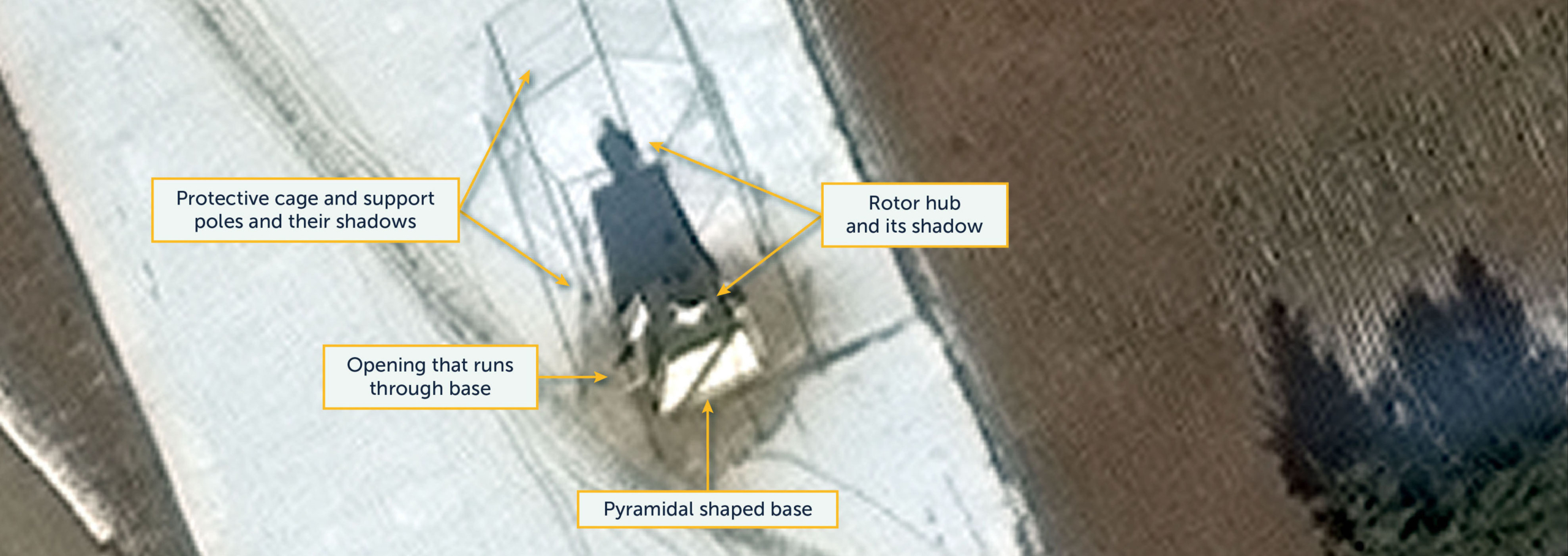

The current helicopter rotor blade test rig at the Panghyon Aircraft Factory consists of a pyramidal-shaped structure measuring approximately 7-meters-by-7meters at its base and 5-meters-by-5-meters at its top. It has an approximately 3.5-meter-wide opening that runs through the base from east to west, allowing access from both sides to the engine and shaft, gearbox, various hydraulic and mechanical controls, and fuel tanks. A rotor shaft extends through the top of the base to a rotor hub where the blades are attached for testing. This structure is surrounded by a tall apparent chain-link protective cage supported by seven poles. This cage is designed to protect nearby personnel, equipment, and structures from damage should there be a catastrophic rotor blade failure during testing.

References

- For an example of social media coverage see Jacob Bogle’s Twitter posting “Unusual Object at the Panghyon Aircraft Plant,” Twitter, March 15, 2021, https://twitter.com/JacobBogle/status/1371487308684353542. The Panghyon Aircraft Factory has sometimes in the past been identified as the Panghyon-Nodongjagu Fabrication/Assembly Plant. In a 2003 book authored by a purported North Korean defector the Panghyon Aircraft Factory was identified as the “8 January (1.8) Factory.” Yi Pok-ku, Top Secrets of North Korean Ballistic Missiles (Tokyo: Tokuma Shoten) 2003. The factory is generally considered to consist of three primary production plants—airframes for fixed-wing aircraft, helicopter, and jet engine—located west and south of the town of Panghyon. It is complimented by a repair facility known as the 4 April Factory at the Panghyon Airbase, 3-kilometers to the north. Interview data acquired by Joseph S. Bermudez Jr.; Kim Kwi-kun. “DPRK Runs Missile Plants in Sunch’on, Kaech’on,” Yonhap, January 9, 2000; and “North’s Production, Export of Weapons Described,” Hanguk Ilbo, 26 February 1991, p. 15. ↩

- The speculation that the, then unidentified, object was a new ballistic missile or ballistic missile launcher was likely influence by the fact that on July 4, 2017, North Korea conducted the first successful test of Hwasong-14 intercontinental ballistic missile (ICBM) from within the Panghyon Aircraft Factory and only 800 meters northeast of the from the unidentified object. ↩

- Kim, Joon-ho. “North Korea Places Strategic Defense Zone Within Pyongyang’s Administrative District,” Radio Free Asia, March 6, 2018. https://www.rfa.org/english/news/korea/north-korea-places-strategic-defense-zone-within-pyongyangs-administrative-district-03062018161653.html. ↩

- Institute of Internal and External Affairs, Inside North Korea: Three Decades of Duplicity, Seoul, July 1975, pp. 43-45. ↩

- Bermudez Jr., Joseph S. Shield of the Great Leader: The Armed Forces of North Korea (London: I.B. Taurus), 2001, pp. 53-54, 147-160, 224-235; and “More Than 134 Factories Producing Military Supplies,” Vantage Point, May 1997, No. 5, p. 4. ↩

- Interview data acquired by Joseph S. Bermudez Jr. Significant factors influencing North Korea’s development of a wartime capability to use helicopters to insert special operations forces into South Korea came from both the extensive use of helicopters during the Vietnam War and the increasingly hazardous use of seaborne routes to insert of such forces. Some sources state that “86 Hughes 500s”, not 87. The 87 figure includes a single Model 300. ↩

- Interview data acquired by Joseph S. Bermudez Jr.; Yu Yin-taek. “North’s Military Reorganization, Mobilization Analyzed,” Pukhan, No. 6, June 1985, pp. 132-141. ↩

- Weapons Systems of North Korea,” Kukbang Kwa Kisul, January 1989, pp. 102-113. ↩

- Ibid.; and “Air Force Day Commemoration Announced,” Naewoe Tongsin, No. 655, 1 September 1989, pp. 1J-4J. ↩

- Interview data acquired by Joseph S. Bermudez Jr.; Central Intelligence Agency. Plant Expansion Panghyon-Nodongjagu Fab/Assy Plt, North Korea, October 1983; and Central Intelligence Agency. North Korea: Jet Fighter Production, April 1984. ↩

- Ibid. ↩

- Ibid. ↩

- It is conceivable that an additional rotor blade test rig could have operated at the Panghyon Aircraft Factory from the late 1980s through late 1990s. The author, however, has been unable to locate any such information supporting this. ↩

- A satellite image collected on January 1, 2019, shows that some sort of apparent activity (e.g., planting of shrubs or trees, etc.) had recently taken place at the site of the original rotor blade test rig at the southern tip of the Panghyon Aircraft Factory. Subsequent imagery of the location, however, shows noting of significance. ↩

- Interview data acquired by Joseph S. Bermudez Jr. ↩